Many industries and purification plants are close to urban centers and that calls for the implementation of more efficient methods to eliminate odors.

While conventional methods may be able to eliminate most of odors, in some cases they are not good enough for odor-sensitive populations. For this reason, it is necessary to develop alternative methods that allow us to explore new opportunities to improve.

Thus, at Sacyr Agua through “Proyecto ODOUR” (EEA GRANTS IDI 20140125), we have developed four efficient technologies to treat odors in industrial processes and water purification. The conditions for these solutions were extremely demanding due to their location and/or characteristics, and they help solve this kind of problems.

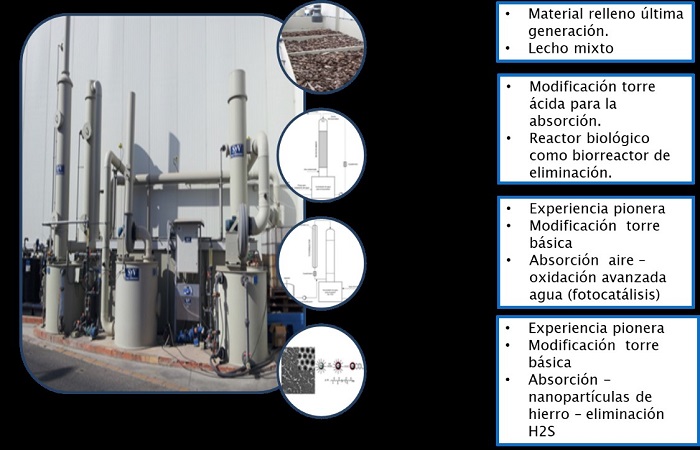

The goal was to develop advanced odor treatment techniques, from the conventional, existing ones, that offer more efficient solutions. They consist of an advanced mixed-culture biofiltration system, a bioscrubber system and its combination with nanoparticles and a photoreactive system.

These solutions were applied to the industrial purification plant of Helados Alacant factory, with the collaboration of Instituto del Agua y de las Ciencias Ambientales of Universidad de Alicante, and it was developed as the follow-up to a previous project on the generation, characterization, measurement and treatment of odors in sewage treatment plants by their source, “Proyecto DESODORIZA” (CDTI IDI-20090908).

“First, we bought a pilot plant and we tested the most used technologies and the most efficient ones, beside from olfactory-metrically and structurally measuring the smell compounds of the purification plant’s environment and designing a management protocol. The desodorization complex consists of four pilot plants with 1.000 m3/h capacity each, (including 2 chemical washing towers – active carbon – biofiltration– ozone).

Afterwards, with this knowledge we executed the biofiltration transformations, bioscrubbing, incorporated a photocatalytic reactor, and configuring iron nanoparticles to accelerate the oxidation of Sulphur components.

Currently, the four developed technologies are part of our corporate know how in tender biddings and public concursations, apart from providing technical support to our developments.

The advanced biofiltration system that successfully provided service for more than 3 years is particularly noteworthy, as a definitive solution to the water pre-treatment line of the ice-cream company, and more recently, in other purification plants, like CAPSA (Central Lechera Asturiana)‘s, in Zarzalejo, where it was implemented as an improvement to the current deodorizing system.

Application of nanotechnology

Now, the principal difficulty we are running into is the application of nanotechnology, due to its costs, but it is a promising solution due to the great catalytic and oxidizing capacity of hydrogen Sulphur of iron nanoparticles”, explains Mercedes A. Calzada Garzón, R&D+i specialist technician of Sacyr Agua.

“Furthermore, as a result of this research and the cumulative experience acquired over the years, Sacyr Agua has its own protocol that combines simultaneous sensory and physical-chemical characterization for a better contrast in results, precise measuring and monitorization”, explains Mercedes Calzada.

Description of the technologies

- Diagnosis: To correctly implement the different technological solutions, a preliminary map of emission hotspots of the study areas was made using an innovative combination of three techniques.

- Advanced Biofilter: To make the most of the biomass’ oxidation capacity and more efficiently oxidize contaminating compounds in the air.

- Bioscrubber: A combination of two technologies: the absorption of the odor compounds in liquid stage and its oxidation through using microorganisms.

- Iron nanoparticles: It has been proven that iron nanoparticles can be applied in eliminating odors due to iron’s high affinity with sulphur compounds, which in many cases are the cause of bad odors.

- Photo-oxidation: hydroxyl radicals can be formed in the presence of catalyzers and UV light and these are capable of oxidizing organic matter.