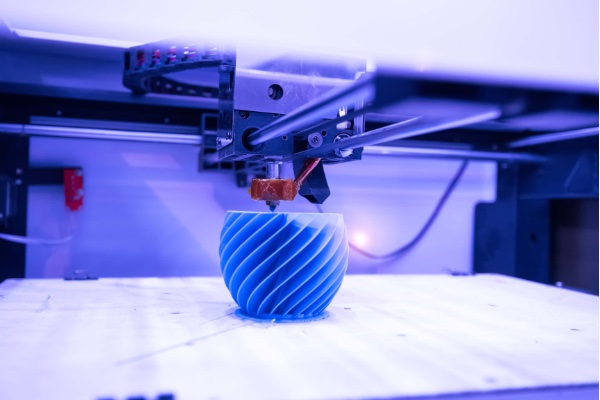

Objects capable of bending, joining and even repairing themselves are already a reality and open infinite applications. Credit: Kinny.

ISABEL RUBIO ARROYO | Tungsteno

In 2013, Skylar Tibbits, founder of the Self-Assembly Lab housed at the Massachusetts Institute of Technology (MIT), explained that it was possible to add a new feature to a 3D printing material: the ability to transform over time. This was the birth of 4D printing, a technology that permits the creation of objects that change after reacting to their environment: they can bend or expand, join together or repair themselves. Although still in its infancy, this technology already holds the promise of many potential uses, from self-repairing pipes to furniture that can assemble itself or clothes that change with the weather.

In its projections for the coming years, strategic consultancy firm Gartner predicts growth in 4D printing. According to the company's latest tech trend reports, startups dedicated to commercialising this technology will attract $300 million in venture capital by 2023. And yet, despite these optimistic forecasts, there is still a long way to go.

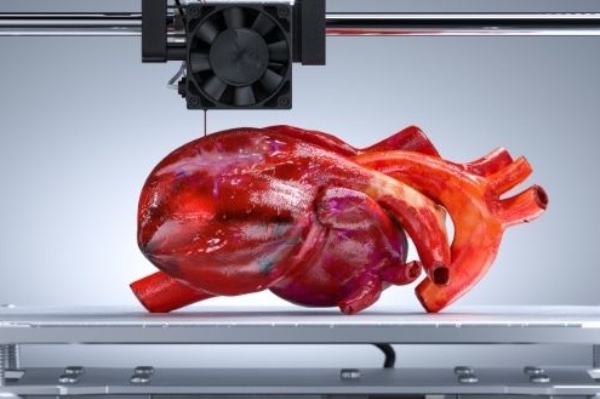

Applications of 4D printing in the medical field are promising: from the development of biomedical devices to the generation of programmable muscles and tissues. Credit: Kostsov.

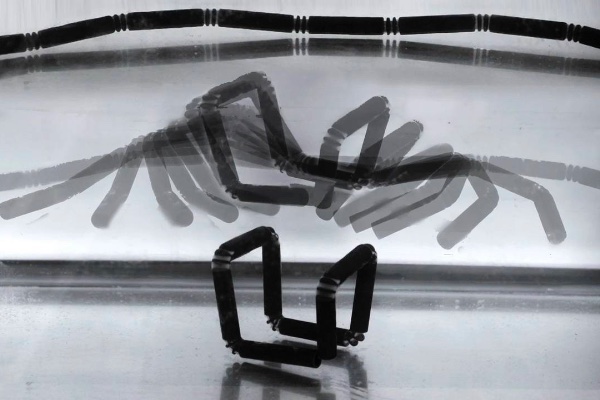

Smart Polymers with memory

To begin with, the materials used today for 4D printing are far less varied than those employed for 3D printing. Among these materials are polymers with shape memory. These smart materials are capable of recording a macroscopic shape, preserving it for a time and returning to its original shape when a stimulus is applied. This stimulus can be a change in temperature, a magnetic field, electric currents or interactions with solvents. An article by the Institute of Polymer Science and Technology of the Spanish National Research Council indicates that these materials have many advantages. The authors mention, for example, their high elastic deformation, low cost, low density and possible biodegradability.

Other materials used in 4D printing are liquid crystal elastomers (LCE). These are characterised by the fact that they contain heat-sensitive liquid crystals that can change shape when a change in temperature occurs. A team of materials scientists at the University of California, San Diego, who have developed such a material, point out that liquid crystal elastomers can facilitate the manufacture of soft robots, artificial muscles and even portable devices.

There are also hydrogels. These are polymer chains composed mainly of water, which could be useful in the medical sector because of their biocompatibility. In this respect, an article from Rutgers University (USA) published in the scientific journal Nature highlights that temperature-sensitive hydrogels have great potential both in tissue engineering and in the development of biomedical devices.

Shape memory polymers, temperature sensitive hydrogels, and elastomers are some of the materials used today for 4D printing. Credit: MIT.

An alternative to robotics

While the applications of 4D printing appear endless, at the moment they are more at the stage of future potential than actual tangible projects. MIT's Self-Assembly Lab predicts that this technology will be used to achieve robotic-like behaviour without reliance on complex electromechanical devices, as well as producing adaptive products, garments or mechanisms that respond to user demands and varying environments.

In fashion, 4D printing could be used, for example, to create sportswear that changes shape and adapts to the feet depending on the activity being performed, or to make smart clothing that can alter itself to match external conditions. In the medical field, it could be used to create programmable biological materials, smart and personalised medicines, or cells and tissues to combat certain diseases.

But if there is one sector in which 4D printing could be particularly useful, it is the construction industry. Although it is still too early to say what kind of structures these materials will be employed in, they could be used to make pipes that can automatically repair themselves if they crack or break, or to create self-repairing floors, walls or asphalt. "Imagine if pipes could expand or contract to change their capacity or flow rate, or maybe even undulate to move the water themselves. These aren’t expensive pumps or valves, but a completely programmable and adaptive pipe on its own," says Tibbits from the laboratory where he works, where he seeks to develop programmable materials for construction.

Will these materials allow us to design self-assembling bridges, shelters or buildings in the future? Will these constructions be able repair themselves if they are damaged by the weather, for example? Will a room be able to change its shape and be used for different purposes? Although on the face of it some of these ideas may seem like science fiction, we will still have to wait a few years to see how far the potential of this technology will actually reach.

· — —

Tungsteno is a journalism laboratory to scan the essence of innovation. Devised by Materia Publicaciones Científicas for Sacyr’s blog.