The concept of the circular economy associated with waste treatment may seem relatively new, but in fact, it dates back some time.

Valoriza Medioambiente (Sacyr’s urban services division) has spent 37 years working on the concept, through the recovery of recycled materials and the generation of renewable energy, among other efforts.

Still, it is evident that the ambitious goals for the environmental management of our waste in the years to come mean that this more “traditional” model needs to evolve through the development and implementation of new treatment technologies that facilitate the better use of materials, preventing them from ending up in the landfill.

Ana Benavent, director of Valoriza’s Innovation department, and Rafael Sánchez Aparicio, director of Valoriza’s Waste Treatment department, discuss all the innovative projects underway that incorporate new waste treatment technologies. There are several highlights among them, including RARx and Microuwas, but today we focus specifically on three others. The three main types of waste are organic, petroleum-derived, and mineral (ferrous and nonferrous). To facilitate waste recovery, the material must be as uniform as possible.

Recycled glass and non-ferrous metals

“We have one related to glass. Before, this material, contained in garbage bags and that was not separated, was thrown all into the landfill. Now, using optical sorting at our plants, we can select and treat it, so it can be recycled for other uses,” explains Ana Benavent.

In October 2020, Ecovidrio included us in the Ecolatras awards, which recognize the work of all the players in Spain’s glass recycling chain, where Valoriza Medioambiente plays a key role. “Thanks to projects like this, Spain currently recycles more than 7 out of 10 glass containers,” she continues.

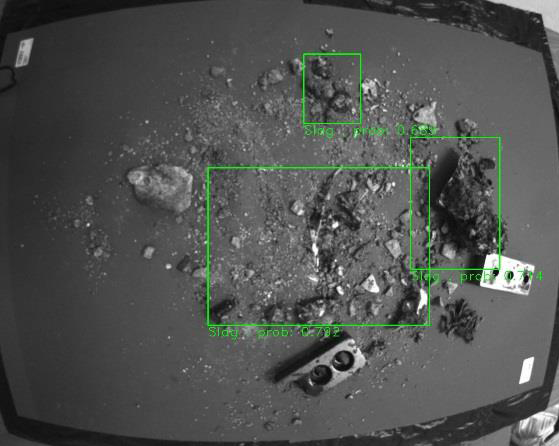

Insight, imaging non-ferrous particle detection

We have another project to detect non-ferrous metals contained in the slag of an incinerator. “When the waste leaves the incinerator, metal materials are selected and the rest is discarded. In slag residue, we know there is 11% recoverable material, roughly 2% of which are non-ferrous metals (copper, aluminum, nickel, precious metals) that can be valuable on the market if separated correctly. We are currently researching a system to determine which slag contains non-ferrous metals for recovery, thus reducing the material deposited in landfills,” Benavent points out.

Digitizing waste

The digitization process, so necessary in countless areas, is also being applied to waste management. “All the information generated in the management of plants, both analytical and environmental, is being digitized. This process streamlines decision-making to determine the best treatment possible,” says Rafael Sánchez. “We are using the Azure SQL program. Once we have digitized all the plant information, we can create big data with a further set of socio-economic information.

The idea is to digitize all of our operations in order to make the most of that information,” Sánchez says.

Biomethane: biogas treatment

Another project involves biogas treatment, converting it to organically-sourced natural gas. “At present, we are defining the Biomethane project and analyzing the viability of biogas treatment, or the viability of biomethane,” Sánchez explains. The Biomethane project can be synthesized by substituting a portion of natural gas consumption (from fossil fuels) for biomethane consumption (from renewable sources with practically the same characteristics). From biogas treatment we obtain biomethane, which is a technologically viable, energy-efficient, and sustainable alternative that can replace natural gas consumption in many homes and vehicles.

Gasometer plant

With its high methane content (50-70%), biogas is generated from the biodegradation of organic matter in anaerobic conditions (absence of oxygen). It is created intentionally (in the case of biomethanization) or naturally as a result of human activity (in the case of livestock or landfills).

“In the waste industry, we contribute to cutting emissions by reducing organic matter in landfills and preventing methane from being released into the atmosphere. We treat the methane we capture and convert it into biomethane. Through the process of anaerobic digestion, we can generate organic fertilizers that help make agriculture more sustainable. Once the biogas is treated, we can also use the biomethane in collection trucks,” Rafael Sánchez concludes.