In Europe alone, more than 16 million tonnes of textile waste are generated every year. Of that amount, 73% winds up incinerated or in landfills, and only 1% is recycled.

Research group TECTEX of the Universitat Politècnica de Catalunya has launched a project that gives a useful outlet to this waste.

This group has created a new construction material from textile waste, preferably indicated for ventilated facade cladding plates within the framework of the RecyBuildMat project.

It is also expected that it can be used as floating flooring, acoustic false ceiling, drywall and other similar applications.

This material's composition (developed in a laboratory) includes binding agents and mineral fillers in addition to textile waste.

The material comes from conventional clothing waste of all kinds. Usually most clothes fibers have cotton and polyester in them. 1 kilo of recycled fibers is used per every square meter of material. In addition, being a residue formed by relatively long fibers and in the form of non-woven fabric, when mixed with cement, it gives advantageous mechanical performance, such as great deformability and resistance to breakage.

The material developed by TECTEX combines lightness and resistance provided by the textile, which also improves thermal and acoustic insulation. In addition, it can incorporate other functions such as self-cleaning or thermal absorption, with special additives.

“We are doing it within the framework of the Retos project, of the Ministry of Science, Innovation and Universities (MICINN). It started in June 2020, and will end in 2024. In addition, for the last 10 years we have been working on construction materials in the framework of challenging projects. The Retos projects reach the lab-level tests scope. To bring it to the market, it will depend on the promoter's desire to introduce this product to the market,” explains Mònica Ardanuy, Professor and head of the Textile Engineering section of the Department of Materials Science and Engineering of the Universitat Politécnica de Catalunya.

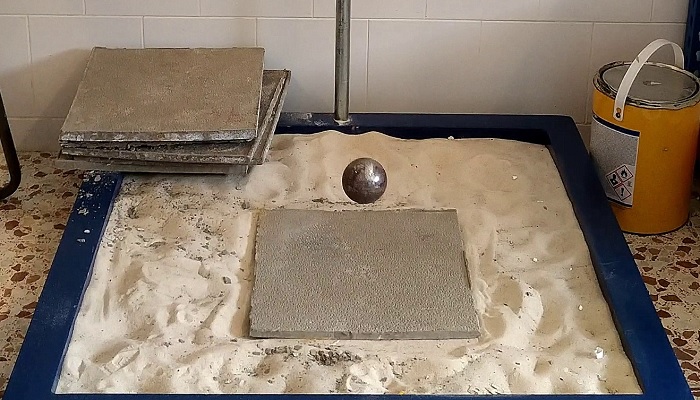

“Within the Retos projects framework, we can ask for a proof-of-concept project to test our materials in an environment close to real-life conditions. Subsequently, if there is any company interested in doing so, it could already be moved to the marketing level. We currently manufacture this material in 30x30 centimeters dimensions" says Ardanuy.

"The plates are equivalent to a type of conventional fiber cement, which is what we commonly know as “uralite”. Uralite used to be a common material to make cover plates, facades, urban furniture, drainage pipes and other similar elements. The dangerousness of asbestos, one of the original raw materials in uralite, banned since 2000, was an important turning point in its production. Today, we have synthetic fibers that can replace asbestos fiber, such as polyvinyl alcohol (PVA) synthetic fibers, explains Josep Claramunt Blanes, Associate Professor at the Department of Agri-Food Engineering and Biotechnology Universitat Politècnica de Catalunya.

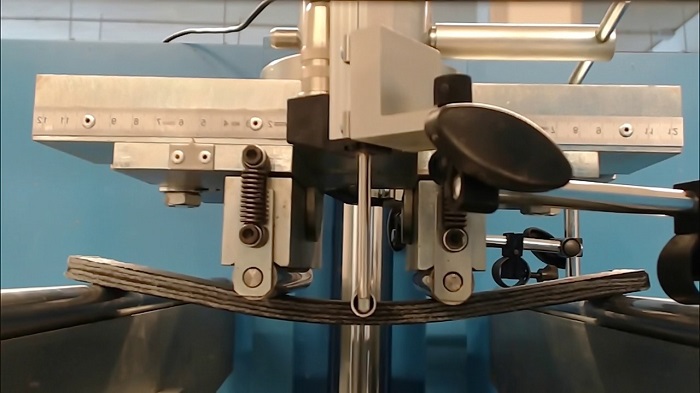

“The difference is that, in conventional fiber cement, short fibers dispersed in the cement are used for reinforcement. This limits the energy absorption capacity of the material. Instead, we use a textile structure reinforcement, which gives resistance properties to the material that regular fiber cement does not have,” explains Josep. "This way we multiply some of the characteristics of fiber cement by 10.”

"Regarding cement materials reinforced with textile fibers, we use a non-woven fabric, which is like a felt, to make it much cheaper than other types of textile structures with weft and warp, commonly used for cement reinforcements,” says Josep Claramunt.

The price is similar to fiber cement and could compete well in many applications. In the case of drywall, so-called ”plasterboard" is more competitive than our material, although its performance is much lower.

As for the facades, current demanding regulations on comfort lead to multilayer construction solutions since it is very difficult to find a material that meets all the requirements. The material we are talking about would be the outer layer of protection and could replace those currently used (natural stone, ceramic, cement composites, aluminum or wood).

At the moment, a cement manufacturing company is very interested in making this material usable. We have also started a collaboration with a company specializing in "panot" paving stones (signature paving stones in Barcelona) to make a pavement prototype with this technology.

“In order to make this material, potential manufacturers should change or modify their current machinery to adapt to the new technology. That's the main issue we run into when we approach companies. We would like to be able to carry out some kind of corporate partnership to go from proof of concept to the real world” underlines Monica.

“As far as we know, there are no other similar materials that use the type of non-woven fabrics that we manufacture. This is difficult to find anywhere else because our fabric is specially designed for this material. As far as we know, there are no other universities or research centers that manufacture this type of non-woven fabrics for this specific type of reinforcement.”