ISABEL RUBIO ARROYO | Tungsteno

Chips are the brains of millions of electronic devices across the globe, from mobile phones and computers to video game consoles, home appliances and even cars. Demand for them has soared during the pandemic, but the global shortage of semiconductors has become a major headache for thousands of companies. While some tech giants have been forced to delay device launches, the lack of supply has also led to shutdowns at car production plants.

"We live in an increasingly digitised world in which chips are absolutely essential," explains Fernando Suárez, president of the Spanish-based Consejo General de Colegios Profesionales de Ingeniería Informática. Microchips are in practically everything we use, "from washing machines, microwaves and ovens to smart-city devices used to control lighting or manage waste and traffic," says Suárez.

Chip shortage puts the tech industry on edge

With the coronavirus pandemic, an unprecedented global semiconductor crisis has unfolded. Buying a PlayStation 5 is currently almost impossible; the same goes for the Xbox Series X, the competing alternative. The shortage of video game consoles is just one example of how the severe chip crunch has put the entire tech industry under pressure. In fact, it has also led to delays in the manufacture and launch of computers and mobile phones.

"There is a serious imbalance in supply and demand of chips in the IT sector globally," said Koh Dong-jin, CEO of Samsung's IT and mobile communications division, in March, as reported in the Financial Times. In fact, the South Korean company is considering not introducing a new Galaxy Note—its flagship model—this year. For its part, Apple estimates it could lose between $3bn and $4bn in sales this quarter because of a shortage of chips, which it uses in devices such as its iPad and Mac computers.

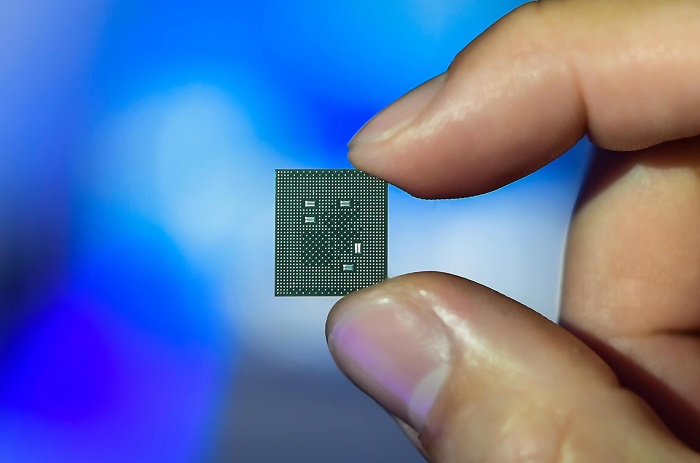

Chips are the brains of millions of electronic devices spread across the globe. Credit: Unsplash.

The automotive sector has also been affected. Multinationals such as General Motors, Ford, Nissan, Honda and Volkswagen have been forced to cut shifts and even shut down entire factories. The chip crisis will cost carmakers more than 92 billion euros and reduce global production by 3.9 million vehicles, according to a report by AlixPartners.

The consequence of a "perfect storm"

Why has there been such a critical shortage of microchips? Before the pandemic, there was already a mismatch between supply and demand, according to Suárez. But the rise of teleworking and teletraining increased the purchase of home devices "at unforeseen rates." Antonio Soto, director of Verne TECH, the emerging technologies division of telecommunications and ICT specialist Verne Technology Group, explains that there has been a "perfect storm of factors that has been amplified by the increased use of technology and devices during the pandemic."

But he insists that this is an underlying problem: "It is a rigid sector where there are many companies designing and very few manufacturing, since setting up a new factory requires an investment of between 10 and 12 billion for a medium-sized plant and about three years of time." The tech giants usually outsource the manufacture of components, something that, according to Soto, is necessary to achieve economies of scale: "If the situation continues as it is now, it is very likely that the current pace of innovation cannot be maintained, and it will be necessary to slow down the market launch of new models."

Tech giants often outsource the manufacture of some components of devices such as smartphones. Credit: Qualcomm.

In addition, at the onset of the pandemic, motor vehicle sales fell sharply. In Spain, the sector's turnover fell by 13% last year following a drop in sales and production, according to the 2020 annual report of the Spanish Association of Car and Truck Manufacturers. "The automotive industry works with very small stocks, so when this decline occurred orders for microchips were reduced and when they wanted to increase them they had to get in line again and this penalised them," explains Suárez.

Is there a short-term solution?

Flex, the world's third largest electronics manufacturing services company, is making one of the most pessimistic predictions about chip shortages, warning that the crisis could possibly last into 2023. Is it possible to avoid it, and are there any solutions to end such a shortage? Not in the short term, according to Suárez. At present, Taiwan and South Korea account for approximately 80% of the global semiconductor manufacturing market: "There is a very high dependence on the factories in these countries," says the computer scientist.

Major powers around the world are trying to reverse the situation. China, the United States and Europe "have seen that this dependence goes against their plans for progress and digitisation and are looking at the possibility of setting up factories." Soto explains that in China "they have seen the problem coming and have been investing for some years in the development of several factories prepared to create this type of device."

In a world in which microchips are now needed in the most unexpected devices, finding a solution to this major global crisis has become one of the priorities of many countries. "Undoubtedly in four or five years these major powers will be able to develop their own microchips, but for the moment I see it as complicated to find a global solution to this problem," Suárez concludes. Finding a solution requires a lot of money and time, so it will not be easy, at least in the short term.

· — —

Tungsteno is a journalism laboratory to scan the essence of innovation. Devised by Materia Publicaciones Científicas for Sacyr’s blog.